In hydraulic systems, the oil is regarded as a structural element that handles many diverse tasks, according to engineers at ARGO-HYTOS. Hydraulic fluid transmits power, lubricates, transfers heat, and transports dirt to the filters. Although there are many causes for failure in fluid-power systems, the condition of the oil is usually the main focus besides mechanical fatigue or overload of individual components. Often, particulates in the fluid are the root cause of excessive wear and component damage.

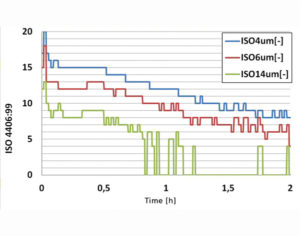

This graph shows an example of particle-concentration measurement during the cleaning of an injection-molding machine with a mobile off-line filter unit.

Undesirable particles can enter a system from the outside, such as through ventilators or past seals; or they are generated by internal wear. Consequences of particle contamination are increased wear, higher component failure rates, lower system performance and shorter life. Dirty oil thus leads to high ownership costs—which is why high-quality filters should be used to keep fluid-power systems clean.

To further drive down operating costs, however, there is heightened interest among machine builders and users to detect component wear early on, so they can prevent damage or breakdown. For example, manufacturers can monitor the proper use and service of their equipment by regularly measuring the number and make-up of particles in the oil and, thus, reduce warranty costs. And from the information obtained, OEMs can identify optimization opportunities to improve their products.

Further, particle-measurement technology is a proven development tool for evaluating wear on pumps, gears, bearings and other critical parts. Here, engineers tend to measure and track both fluid purity and any wear of the component itself. In addition, particle measurement is increasingly used to help control cleaning or rinsing processes. Here, quality guidelines must ensure that the rinsed parts or wash systems satisfy specified purity requirements. Producers and users of cleaning equipment meet this demand by integrating particle-measurement technology in their facilities, letting them document every cleaning process.

OPCom particle monitor

Particle-measurement options

When considering which method is best suited for monitoring, economic considerations generally come first. That includes not only the cost to analyze a single oil sample, but also the risk of failure and the resulting costs of damage or downtime.

Fortunately, manufacturers of contamination-control systems like ARGO-HYTOS offer many different sensors and instruments for particle measurement that enable effective and inexpensive monitoring in most every application.

Automatic particle sensors typically offer the best price-performance ratio, allowing online measurement of the size and number of particles in real time. Alternative manual procedures such as microscopy or gravimetry are complex, error-prone and inefficient.

Examples of component damage due to contamination

The advantages of online measurement over conventional laboratory analysis lie not only in simpler handling and lower total costs, but especially in gapless measurement. The measured data do not reflect an arbitrary snapshot but detect continuous change. Thus, state-dependent predictive maintenance is possible.

Experienced users know that accuracy is largely determined by the care taken in sampling and analysis. Particularly with regard to particle concentration, improper sampling and analysis can significantly distort the measurement results. Automatic particle-measuring instruments guarantee optimum repeatability and comparability across many tests.

Here’s a look at some of the products available from ARGO-HYTOS that are key to modern particle-measurement technology.

Optical particle measurement. As a standard for online particle measurement, the optical method based on the light-blockage principle according to ISO 11500 predominates because it is inexpensive and quite reliable.

Here, particles to be counted are optically measured in a capillary. If there are no particles in the measurement cell, light shines unhindered on a photodiode. However, a particle that passes the measurement cell blocks the light beam, generating a shadow on the opposite photodiode. Shadow size is proportional to the size of the particle and, thus, can be used to characterize the contaminant.

Subsequently, the measured number of particles is related to the measurement volume and reported in terms of concentration. Results can be represented according to different standards, which the user can select on the measuring instrument. In addition to the common standard ISO4406:1999, ARGO-HYTOS devices also offer SAE AS 4059, GOST 17216 and NAS 1638 reporting.

OPCount particle counter

Particle counters. Particle counters are particularly suitable for extremely accurate measurement of oil contamination in the laboratory or the field. ARGO-HYTOS’s latest-generation unit, the OPCount, is designed for use in hydraulic machines. Its integrated volumetric particle measuring cell guarantees that each particle flowing though the sensor is accurately measured.

An internal pump allows online, bottle and tank measurements. The device can thereby intuitively be operated via a touch display and convenient measurement profiles. Measuring data and additional information about the sample, such as temperature, viscosity or oil type can be stored or printed. Any accessories required for taking measurements stow neatly inside the device, which simplifies handling.

The OPCount particle counter is often used for routine monitoring, quality control or failure analysis. It lets users create databases from which one can help understand and track the history of the oil in a machine. From this, engineers can obtain valuable information on the cleanliness, condition and performance of the equipment.

OPCom FerroS wear sensor

As an option, users can also connect an ARGO-HYTOS LubCos condition sensor to the OPCount. This allows tracking of additional parameters such as temperature, humidity and oil quality.

Particle monitor. For systems where particle measurement must not only be automatic but durable, a permanently installed device is needed. Here, compact and robust particle monitors are recommended that can easily be integrated into a hydraulic system.

Stationary and mobile equipment can face demanding operating conditions. This can include high pressures and temperatures, dirt, humidity and vibrations. Therefore, measurement equipment with a robust design is essential to ensure long-term operation. All components, including light source, detector and housing must meet stringent requirements. As one example, the ARGO-HYTOS OPCom particle monitor—with an IP67 protection class and corresponding shock and noise immunity—is suited for demanding applications. A proven application for online particle measurement is monitoring oil cleanliness in heavily loaded industrial applications such as presses or injection-molding machines.

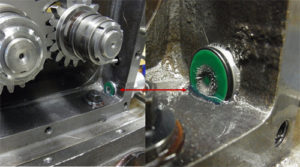

Gear set with OPCom FerroS and accumulated particles

Inductive particle measurement. Inductive metal-particle detectors are used for selective detection of ferromagnetic wear particles. Specifically designed for gears and an economical alternative to conventional metal-particle detectors, the OPCom FerroS wear sensor works on the principle of a magnetic plug and accumulates ferromagnetic particles using a permanent magnet. A coil in the sensor head detects the accumulated particles and generates a measurement signal proportional to the accumulated amount. For continuous measurement, the sensor can be cleaned automatically. Using this proven measuring principle enables easy integration of the sensor directly in the system. In contrast to comparable sensors, it works even when no flow is generated.

ARGO-HYTOS

www.ARGO-HYTOS.com

The post Cleanliness and wear monitoring via modern particle-measurement technology appeared first on Sealing & Contamination Control Tips.

Filed Under: Filtration/Contamination Control, Sealing & Contamination Control Tips