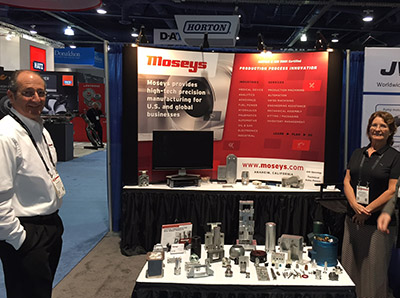

I had the chance to talk with Bob Mosey of Moseys, a precision manufacturer that specializes in providing manufacturing services for a lot of different OEMs, including those in the hydraulic and pneumatic industries.

I had the chance to talk with Bob Mosey of Moseys, a precision manufacturer that specializes in providing manufacturing services for a lot of different OEMs, including those in the hydraulic and pneumatic industries.

“We can take a part from concept through final production and into final packaging if the customer wishes, so it’s a pretty wide value chain. We do most of this in house, and the fact that we’re in Southern California, just about every material and outside process that’s required is right there is local to us, so we can pretty much build the whole thing for them,” said Mosey.

Mosey said that medical devices is probably the company’s biggest industry served currently, and the company’s general outlook is good—but they are also looking more at the energy sector.

“All the forecasting information says things are going to go up. I see oil and gas coming back a little bit, and that’s a big part of the hydraulic industry. For us, we’re really focusing on that industry on purpose because so much of the product line fits the things that we do—and the way that we work with not necessarily high production work but more production repeat business. There, we’re building the same thing over and over throughout the year in smaller quantities,” he said.

For his customers, they are most concerned with quality, delivery—and of course they always want to talk about price.

“We’ve addressed all those needs in a lot of different ways. We put a lot of automation in years ago and continue to expand on that—so that makes our response time quicker. Once we have a product line up and running, we can respond really quickly with that. That also helps keep our cost down, so I think that we’re cost competitive … maybe not with China. But, if you look at just individual piece price, if you look at fully loaded, fully landed costs, I think we’re right in there.”

Filed Under: Pneumatic Tips