Hydraulic and pneumatic hose safety can be ensured by using quick-connect fittings or quick couplings that make a repeated connection and disconnection between fluid lines and the equipment they are attached to. Quick couplings are used in both hydraulic and pneumatic applications, and are designed for easy hand operation.

CEJN’s X65 quick connect couplings and nipples feature an extra security locking offers added protection against involuntary disconnection.

These safety devices feature a male end—or plug—that is inserted into a female end—or socket—to make a secure, leak-tight seal.

In extremely high-pressure hydraulic applications, a leak or accidental disconnection can cause serious personal injury or damage to machinery. In pneumatic applications, compressed air presents great dangers for hose whip.

They usually feature a one-way sleeve to allow for break-away with a tool when a coupling is clamp mounted. Two-way sleeves allow for one-hand disconnection. In two-way designs, twisting and pulling the two ends breaks the connection.

One of the most common designs is the flat face design, which is available as push-to-connect, threaded or screw-in. They eliminate any cavities where fluid or air can rest, thus removing the chance for trapped pressure and leakage. Flat face couplings provide high flow and low pressure drop and their sleeve-locking feature reduces the chance of accidental connection, removing leakage and spillage risks.

Ball or bearing types feature spring-loaded balls lodged in cavities to make the connection. They can be disconnected with just one hand.

Miniature quick-disconnects from Beswick Engineering. These dry-break designs are non-spill couplings.

For aggressive media, one should use non-spill designs. Non-latching couplings are heavily used in medical and test applications where frequent change-outs are common. Bayonet couplings feature two plugs that are engaged and locked by completing a quarter-turn to push the male end into the female socket. Disengaging and separation is the same, but in the opposite direction.

Keep safe design in mind

Remember: When selecting a hose coupling assembly, the lowest rated component is the actual safety factor. So if you have a 5,000 psi-rated hose but a 4,000 psi coupling, the safety factor of the assembly is 4,000 psi.

When working with aggressive media, using color-coded or key locks helps avoid cross connection. Ensure sealing materials and all internal materials are compatible with the fluids being used. And if available, check alert rings to ensure a system is properly connected; for example, some manufacturers use a red alert ring that disappears when a system is properly connected.

The dangers of oil injection injuries are real with high-pressure hydraulics. This is why hydraulic high-pressure quick couplings require more than just a Teflon tape seal or thread sealant. The higher pressure you are using, the stronger the seal required—ranging from rubber metal seals and copper seals to fully metal seals.

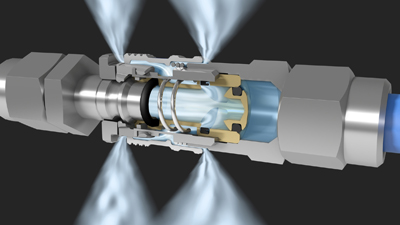

During disconnection, CEJN’s eSafe vents the down steaming pressure, eliminating recoil and reducing noise level.

Ensuring a safe end of life with quick couplings is also critical. When a coupling fails, you don’t want it to explode and have locking balls flying out. The design should fail with predetermined leakage paths so fluid comes out slowly.

To avoid unplanned failure, conduct regular inspections and maintenance to check for wear and damage. Ensure there is no brinelling occurring where the locking ball is. Also, a hose could fail before the coupling so a visual inspection for abrasion and cuts is necessary.

In pneumatic applications, safety couplings—such as CEJN’s eSafe—are designed to vent compressed air when the sleeve is pulled back while holding the nipple and hose assembly in place. After all the air is vented out of the system, only then does it release the hose, which prevents hose whip, popping noises and even moisture from escaping the system.

Filed Under: Fittings, Couplings & Adapters, Hose Assembly Tips, Slider