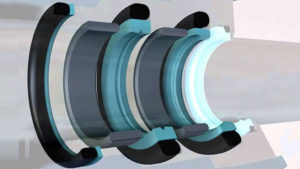

Literally, every fluid power system counts on soft-sealing technology to contain high-pressure liquid, allowing hydraulic energy to transmit useful work. The most common rubber technology in today’s fluid power system is synthetic, such as Buna nitrile or urethane. Each type of polymer has its advantages, but they also differ in their disadvantages.

The hardness of polyurethane makes it excellent in high-pressure applications requiring resistance to extrusion. However, urethane isn’t the single source rubber compound to be used in all hydraulic systems. As good as urethane is, it doesn’t play well with water.

The hardness of polyurethane makes it excellent in high-pressure applications requiring resistance to extrusion. However, urethane isn’t the single source rubber compound to be used in all hydraulic systems. As good as urethane is, it doesn’t play well with water.

When water exists in your hydraulic system, either intentionally with high water-based fluids or accidentally with contamination, those H2O molecules make life tough for urethane. The reaction that occurs between urethane and water is called hydrolysis. As water saturation level increases, and especially in the presence of heat, the seal material will break down as a chemical reaction occurs between the rubber and water.

The physical result of the seal breakdown results in a seal that physically cracks and breaks apart as the polymer bonds can no longer hold tight. With more water or more heat, the hydrolysis effect accelerates, and seal breakdown occurs within days or weeks.

Although occasionally engineers will select the incorrect material for their application, such as urethane for a water-glycol application designed to be fire-resistant, it’s more common that water contamination infects traditional hydraulic oil. Contamination doesn’t have to exist as free water, as even increased oil humidity will accelerate hydrolysis in the presence of heat.

The solution to the problem of hydrolysis is first to choose the correct seal polymer for your application. For high water-based fluids such as emulsions or glycols, using Buna nitrile, thermoplastic or other suitable synthetic rubber is your first step in the fight.

The second step is to ensure water contamination is controlled and kept minimal. If you have free water in your hydraulic system, you have problems more significant than just hydrolysis. It’s essential to monitor oil for clarity and color, and if you don’t electronically monitor oil humidity, taking part in an oil analysis program will help. Regular samples taken and analyzed tell you more about the health of your hydraulic machine than just water contamination alone.

On a side note to oil and humidity, be aware that the type of oil you use may affect its tendency to attract and hold water. Bio fluids made from vegetable oil are an excellent choice for use in areas subject to environmental awareness. Still, these fluids often have increased hygroscopic tendencies, meaning they absorb water at a higher rate, even from the air. Be sure your bio fluid is free from humidity, especially in damp environments.

That being said, modern urethanes have evolved to resist the damaging effects of hydrolysis. Special thermoplastic polymers of urethane provide a hig- pressure, extrusion resistant seal with none of the side effects. If you have a particular application where water exists in conjunction with high pressure, reach out to your sealing technology partner to help you choose the best seal for your purpose.

Filed Under: Sealing, Sealing & Contamination Control Tips