The complex design of tunnel boring machinery requires hundreds of hydraulic seals to maintain clean, efficient operation.

Contributed by Daniele Agnesi, Engineering Manager, Hallite Italy

A global trend in increased spending on road, railway and infrastructure projects is driving demand for the tunnel boring machinery (TBM) needed to do the work.

Tunnel boring machinery operation

In countries like China, Japan, Italy, South Korea, Norway, and Germany — where some of the world’s longest and most extensive tunnel networks connect major cities and oftentimes neighboring countries — TBMs are used by public utilities and transport companies to improve mobility of people and goods, minimizing commute time and stimulating commerce.

TBMs are massive, ranging from 1 to 20 m (3 to 66 ft) in diameter, weighing thousands of tons, and more than 100 m (328 ft) long. Composed of a complex assembly of several systems with circular cross-sections including a rotating cutter head, TBMs are used to excavate soil and rock for development and expansion of railways and utilities like water, sewage, hydropower and pipelines. To contain the pressurized fluids in a TBM’s hydraulic cylinder system and keep it in motion for efficient operation through a specific terrain and rock type, an equally complex configuration of hundreds of high-performance, fit-for-purpose hydraulic seals is required.

We will examine some specific types of hydraulic fluid power seals commonly used in a TBM along with their material composition. We will conclude by reviewing an innovative sealing application on a TBM used in Italy that demonstrates how OEMs can achieve optimum reliability and productivity when they choose sealing products supported by a manufacturer with deep engineering design and field experience.

Seals and materials

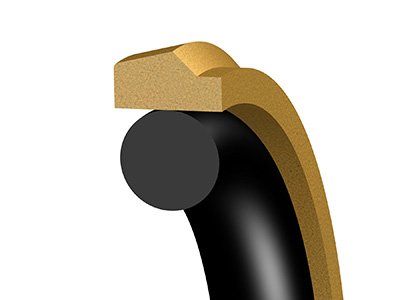

Hallite’s P16 single-acting piston seal

Piston seals, rod seals, rotating/swivel seals and wipers/scrapers are some of the most commonly used seals in a TBM cylinder system. Each seal performs a unique function while working together with many others. Working together, they offer the TBM hydraulic cylinder system the highest level of protection from excavated material.

Piston seals prevent pressurized fluid from leaking across the piston as system pressure pushes the piston and rod assembly down the cylinder bore. Both single- and double-acting piston seals are manufactured in materials such as high-performance polyurethane, rubber/fabric composite, PTFE or polyester elastomer. A piston seal is selected based on the amount of time and work to be done by the cylinder and in what direction and at what pressure. Since a TBM tunnels hard rock over long distances, it requires piston seals designed to operate in heavy duty, high-pressure, high-temperature environments.

Piston seals are used with integrated or separate back-up rings and guide rings. Guide rings are manufactured of resin-bonded fabric and engineered plastics that steer the piston in the cylinder bore and rod in the cylinder head of a hydraulic cylinder, preventing damage from side loading as they hinder metallic contact between axial and rotational components.

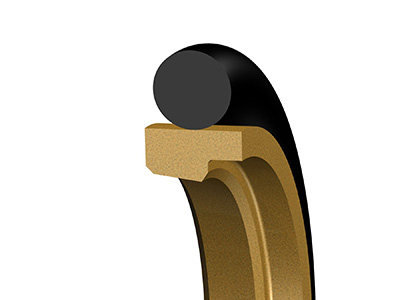

Hallite’s R16 modified single-acting rod seals

Rod seals hold pressure in the cylinder by preventing fluid leaks. Leakage through the rod seal can reduce equipment performance and in extreme cases cause environmental issues. Rod seals manufactured in high-quality PTFE products combined with an elastomer energizer provide maximum performance. Wipers composed of high-performance PTFE materials — like Armorlene HLX, a special bronze-filled PTFE based sealing material — offer robust wear and scraping capability and a large temperature and media compatibility range.

Rotating/swivel seals are designed for slow rotary applications, such as hydraulic swivels, which allow the transmission of pressurized services between the chassis and body of mobile hydraulic equipment. Seals manufactured of high-performance PTFE provide low-friction qualities that eliminate potential sticking on start-up.

Wipers/scrapers prevent contaminants such as dirt, dust and moisture from entering the cylinder as they retract back into the system. Contamination can cause significant damage to the rod, cylinder wall, seals and other components, and is one of the primary causes of premature seal and component failure in a fluid power system. A wide range of hydraulic wipers are manufactured in high-performance polyurethane, such as Hythane TPEs, nitrile and other polyester-based materials. Press-fit metal caged ranges are also available.

The case for Italy

Italy is predominantly mountainous and hilly (approximately 77%) making it a major focus for tunnels and host to some of the world’s largest road and rail TBM projects. Consider for example the 15.87-m diameter (52.06 ft) Santa Lucia road tunnel for the A1 motorway near Firenze south of Bologna. This project involved one of the largest TBMs ever used on a project in Europe. Others include the 15.55-m (51.01 ft) A1 Sparvo highway tunnel and Sicily’s 15.08-m (49.47 ft) Caltanissetta highway tunnel. Railway work is also a significant focus1. The Lyon-Turin railway project, one of the largest rail projects in Europe, includes a 57.5-km (35.7 mile) base tunnel that will link the international stations of Saint-Jean-de-Maurienne and Suse, reducing travel time between Lyon and Turin from almost four hours to less than two2.

These kinds of projects define the Italian market where demand for reliable, high-quality hydraulic sealing solutions designed to keep pace with the country’s strong TBM market resulted in development of a durable, high-performance sealing application for a local OEM. Hallite developed a sealing system to address a challenge the OEM faced in the heavy-duty, high-pressure, and high-frequency — influenced by a short stroke — operation of two crawler tensioning cylinders.

The bore dimension of the first cylinder was 450 mm (17.72 in.) with pressure around 450 bar, and the bore dimension of the second cylinder was 320 mm (12.59 in.) with standard 400 bar pressure and potential peaks of 600 bar. This was impacted by a high gap on the piston and the rod.

To resolve the issue, a sealing package was designed for both cylinders that included rod and piston seals manufactured in a range of profiles and PTFE materials, and based on a robust buffer and rod seal designed for high pressure. Included were special modified R16 single-acting rod seals featuring an anti-extrusion ring and supported by the SRB — a unique high-pressure buffer seal design from the Armorlene range. The piston seal assembly included double-acting GP2 seals supported by special P16 single-acting piston seals on each side. The P16 seals feature the same anti-extrusion ring as the R16 for effective, low-friction sealing. Tests performed in the customer’s facility validated the effectiveness of the solution.

As TBM projects increase in Italy and worldwide, Hallite will continue to partner with equipment manufacturers to develop new fluid power sealing materials and technologies to meet their unique requirements.

Hallite

www.hallite.com

References:

1: Tracking the world’s Mega-TBMs – TunnelTalk, Discussion Forum

2: S2IP consortium wins Lyon-Turin rail tunnel contract – Railway Technology

Filed Under: Sealing & Contamination Control Tips