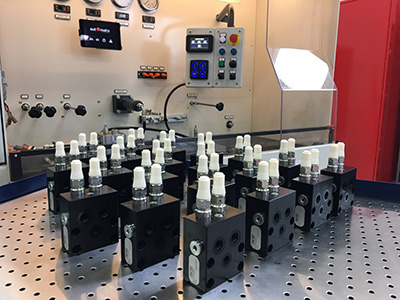

Load holding valves from Valvole America are available in a very wide range of cartridges or assembled into valve blocks. They secure the last commanded position of an actuator by preventing fluid from escaping work chambers, with “zero” leakage. They ensure low leakage when closed, with less than 5 drops/min when the valve closed with 85% of set pressure applied to load holding port.

They are rated for standard maximum operating pressure of 350 bar (5,000 psi), and optional maximum working pressure of 420 bar (6,100 psi). They offer reliable and stable hydraulic performance over full temperature range of –30° to 100°C (–22° to 212°F).

They are rated for standard maximum operating pressure of 350 bar (5,000 psi), and optional maximum working pressure of 420 bar (6,100 psi). They offer reliable and stable hydraulic performance over full temperature range of –30° to 100°C (–22° to 212°F).

With system cleanliness level recommended at ISO 4406 19/17/14 for all high-pressure components, they offer a high level of contamination resistance. The critical components of the load holding valve are hardened and do not sustain performance degrading damage with normal levels of fluid borne contamination.

Finally, they can come with an unsealed or sealed pilot piston. The pilot piston can be provided with a glide ring for reduced hysteresis to allow a low level of leakage which is beneficial for bleeding air from the pilot chamber on commissioning. The pilot piston can also be provided with positive seals for critical low flow or master/slave circuits where no leakage through the pilot chamber can be tolerated.

Valvole America

Valvoleamerica.com

Filed Under: Mobile Hydraulic Tips