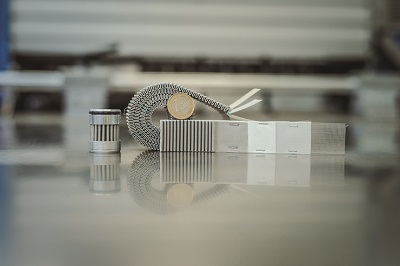

The smallest non-woven filter element ever produced by Argo-Hytos, Kraichtal, Germany, has a diameter of just 25 mm (0.98 in.) and a height of 35 mm (1.38 in.). It is used in the control block of a wheel loader.

The Argo-Hytos mini filter has about the same diameter as Euro coin.

The miniature filter from Argo-Hytos is only the size of a thumb but, according to company officials, it does not compromise on functionality. A multi-layer filter fleece encloses the perforated support tube. Close cooperation between development engineers and the prototype shop ensured the process-reliable manufacturing of the necessary materials.

Complex process steps must be mastered despite the tight working dimensions. These included:

• Material cut to width

• Four-layer pleating of the materials

• Optimization of the pleat geometry

• Cutting the pleat pack to length

• Bonding of the longitudinal seam

• Dosing of minute quantities of glue

• Secure fixation of all parts during curing

• Assembly of support tube and end cap.

The filter is about the size of the worker’s thumb.

After manufacturing, the miniature filter elements are then subjected to quality testing, which they have passed without complaint. In sample production, process reliability is also assessed and documented, which is important for future series production.

ARGO-HYTOS

www.argo-hytos.com

Filed Under: Sealing & Contamination Control Tips