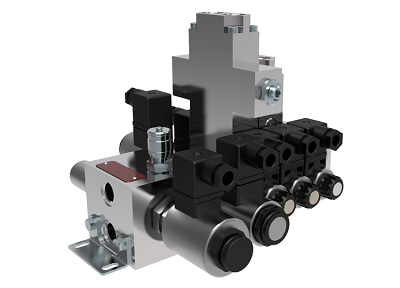

The modular valve system RPEK1-03/B from ARGO-HYTOS, Baar, Switzerland, is a flexible system suited for a wide range of applications in mobile and stationary machinery. The RPEK1-03 (size 03) sectional directional valve, with a maximum flow of 20 l/min (5.3 gpm) per section is the basic component of the assembly. Thanks to a large number of horizontal and vertical sections, combined with screw-in valves, numerous types of open-center circuits can be created.

The ARGO-HYTOS RPEK1-03 valve system is designed to handle a wide range of mobile and stationary applications.

According to company officials, users appreciate the flexibility offered by the modular design when developing hydraulic systems, implementing various system modifications or making repeated design changes. Due to the ease of modification and extension, customers save on development time and financial outlays, including labor costs.

The total manifold assembly consists of four sub-sections:

1. The inlet section connects the entire manifold assembly to the pressure and tank lines of the hydraulic system. It is possible to enable pressure reduction or an unloading circuit by using 7/8-14 UNF (B2, C-10-2) valves. The inlet plate can be installed at the center of the assembly and the module manifolds with valves can be connected to it on both sides. In this way, up to 16 sections can be connected. The modular inlet manifold can be used for operating pressures of up to 250 bar (3,626 psi) and a total flow rate of 60 l/min (15.9 gpm). BSPP and SAE industrial standard threads are available for connection to the circuit.

2. Horizontal sandwich plates with cavities for any screw-in valve in size ¾-16 UNF (A2, C-08-2) allow for a wide range of control functions in ports A and B, which lead to the connected actuators. The following valves can be used:

• Check valves and pilot-operated check valves

• Flow control valves and flow regulators

• Pressure control valves

• Overcenter valves for load motion control

• Any other solenoid-operated valves for directional control of the flow.

3. Vertical sandwich plates. Here, the company offers throttle valves with bypass check valve, pilot-operated check valves, and a number of cover plates with horizontal and vertical ports to connect the actuators to individual sections.

This circuit shows a typical example of a compact, multi-functional modular manifold assembly for controlling three actuators.

4. The basic sectional directional control valves mentioned above, end plates and end-plate valves complete the modular RPEK1-03 assembly.

These products are typically used for cylinder functions in stationary and mobile systems; and for open-center auxiliary functions in mobile and stationary machinery — for example crab steering and blade control.

According to the company, the RPEK1-03 valve system offers several advantages and benefits. These include:

• A cost- and space-saving concept.

• No in-line body needed.

• Can be used separately or in combination with SMA 05 power packs.

• Horizontal and vertical plates, and cavities for standard screw-in valves.

• Available with numerous connectors, including DIN, AMP and DEUTSCH-DT04-2P.

ARGO-HYTOS

www.argo-hytos.com

Filed Under: Mobile Hydraulic Tips