Air leaving a compressor is hot, dirty, and wet. Left untreated, it can damage products and shorten the life of downstream equipment. In pneumatic systems, contaminated air leads to premature wear in valves and cylinders, attacks seals and causes them to leak, results in rust and corrosion in tools and piping, and is generally the root cause of faster breakdowns and higher maintenance and operating costs.

Thus, air needs to be filtered (as well as cooled, dried, regulated and lubricated) before it can be used.

Air-line filters clean compressed air, and they typically come in three types. General-purpose pneumatic filters are designed to remove solid particulate contaminants such as dust, dirt, pipe scale and rust, and separate out liquid water and water droplets. Coalescing filters remove oil aerosols, and activated-carbon filters remove oil vapor.

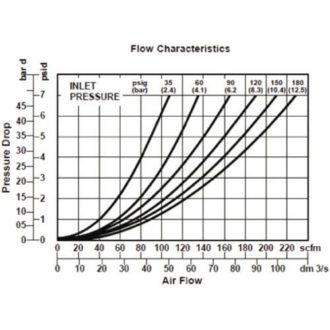

The chart shows typical flow characteristics of a filter element with a specific micron rating.

Filters should be installed in air lines upstream of regulators, lubricators, valves and actuators. It goes without saying that it is important to use the correct filter for an application. Here are two important considerations when sizing and selecting filters for compressed-air systems.

Micron rating.

Particle-removal filter elements are rated by the size of particles they trap. The smaller the micron rating, the smaller the particles it will capture. Thus, a 40-micron element, for example, is designed to remove particles 40 microns and larger. However, for a given element size, the smaller the micron rating, the higher the pressure drop across the filter. The service interval between cleaning or replacing the element is also shorter for smaller micron filters, as small holes plug more quickly than bigger holes.

In industrial applications, standard general-purpose filters are rated to handle particulates 40 microns or 5 microns in size. Depending on the industry and application, other sizes can include 20, 25 and 75 micron filters. Higher-efficiency filters are also available to remove even smaller particles—1 micron or less.

The downstream components and equipment determine the micron rating a filter element requires. Most industrial equipment and tools like air wrenches typically only need 40-micron filtration, while more-sensitive components and instruments typically demand 5-micron elements. Food, beverage and pharmaceutical applications routinely demand even finer filtration. It’s a good idea to consult with the equipment manufacturer to determine exact filtration requirements.

But in general, because smaller micron-rated elements have a higher pressure drop across the filter and shorter element life, don’t opt for a finer filter than necessary. Specifying a 5-micron filter when a 40-micron unit will suffice actually increases energy consumption, change-out intervals, and overall operating and maintenance costs.

Flow capacity.

In addition to contamination-removal efficiency, also consider the airflow demands of the application. Filters are generally available in many sizes to handle flows as high as 1,000 scfm. After engineers understand the required flow for a pneumatic application, select the proper-size filter by determining the maximum allowable pressure drop across the filter.

To help with that task, most manufacturers supply flow-versus-pressure drop curves for a given element. As noted in the example chart shown nearby, they often show performance at several different inlet pressures. To use the chart, first determine the application’s inlet pressure. If your operation is at a different pressure than shown on the chart, interpolate between curves to obtain the suitable pressure and flow performance. Next, determine the acceptable pressure drop across the filter. Generally, for good performance experts recommend a filter with a 2 to 5 psig pressure drop. Then find the flow in scfm. If flow is too low, select a larger port or body size to give the required flow. Likewise, if flow is higher than necessary, select a smaller unit to obtain the required flow.

A manufacturer may offer several different filters with a particular port size, but all may have different flow capacities. Typically, specify the product with the lowest pressure drop at the required flow rate. Also note that the curves are based on a dry element; a wet element will have lower flow and higher pressure-drop ratings.

While efficiency and flow are two important filtration parameters, there are others. Next, we’ll look at some practical considerations for selecting pneumatic filters.

The post How do you select an air filter? appeared first on Sealing & Contamination Control Tips.

Filed Under: Sealing & Contamination Control Tips