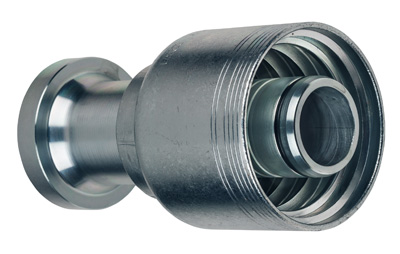

Eaton, Eden Prairie, Minn. offers the 4S/6S series of spiral hose fittings, which are said to feature major advancements that help provide a robust, practical and complete engineered hose-assembly system. The fittings are designed for high-pressure hydraulic systems commonly found in mobile and industrial equipment used in the machine building, mining, construction and agriculture markets.

Eaton, Eden Prairie, Minn. offers the 4S/6S series of spiral hose fittings, which are said to feature major advancements that help provide a robust, practical and complete engineered hose-assembly system. The fittings are designed for high-pressure hydraulic systems commonly found in mobile and industrial equipment used in the machine building, mining, construction and agriculture markets.

The updated fitting series now features Dura-Kote plating for superior corrosion resistance, a non-brazed nipple design to decrease the risk of product failure, and Class 0 cool-down leakage following impulse testing as outlined under SAE J1176 when coupled with Eaton hoses. Built with captive nuts instead of crimp nuts, the fittings prevent cracking, even if over-torqued.

Because durable, reliable engineered hose assemblies are critical to machine performance, the 4S/6S series of fittings are designed to work with the majority of Eaton’s spiral hoses, and the assemblies meet or in most cases exceed industry requirements set by EN, SAE and ISO standards.

The 4S/6S fittings have also been simplified to a common design, and can be used on the widest variety of Eaton rubber hydraulic hose products, reducing inventory requirements and making management easier. The fittings are available in sizes -12 through -32.

Eaton

eaton.com/4S6S-Fittings

Filed Under: Hose Assembly Tips