By Josh Cosford, Contributing Editor

Modern hydraulic hose is no less susceptible to abrasion opportunities than in the past. Some applications cannot avoid abrasion, such as booms or arms on mobile lifts and similar equipment. In addition, any joint that pivots or rotates requires a flexible connection between two fixed connections, and sometimes the movement of the hose against fixed surfaces or other hoses is unavoidable.

Hose has come a long way from the fabric outer layers from decades ago and today’s hose cover (not to be confused with hose wrap) offers excellent abrasion resistance right from the factory. Some hose manufacturers even offer upgraded hose designs with covers extra-resistant to abrasion and wear. However, for any application experiencing hose vibration or contact, you should also consider third-party hose wrap.

A wrap doesn’t just protect the hose from premature wear but protects your hydraulic system from catastrophic failure. A hose leak often results in complete machine shutdown until the hose can be remanufactured and replaced. I don’t know anybody who appreciates unexpected downtime, so a hose wrap must be considered mandatory for any machine with potential for wear. And hose wrap isn’t just something you should specify when ordering a new hose, but rather a sacrificial item that wears as intended and may be replaced as required to keep the hose below fresh.

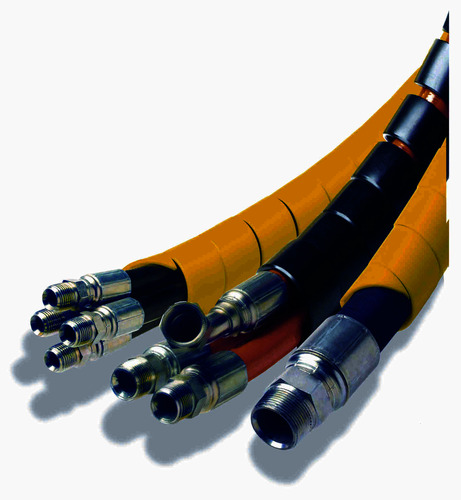

There are two standard methods to protect a hose with a wrap – plastic spiral wrap and nylon sleeves. Nylon sleeves wrap the entire hose assembly from end to end, where clamps hold it firmly in place atop the fittings on either end. The nylon resists friction, cuts and kinks while providing an extra barrier of protection from any ambient contamination such as oil or fallout.

Although nylon wraps require removing the hose to replace, some manufacturers offer Velcro sleeves that may be installed or replaced while the hose remains installed on the machine. Although the chance the Velcro comes loose does exist should the seam catch on something stationary, it still offers excellent abrasion resistance.

Spiral wrap is made from various abrasion-resistant plastics, such as high-density polyethylene, and is indeed very strong and long-lasting. Spiral wrap has many benefits, such as field installation while the hose remains on the machine. Although it does little to protect the hose from the surrounding environment, it provides superior protection from friction and wear.

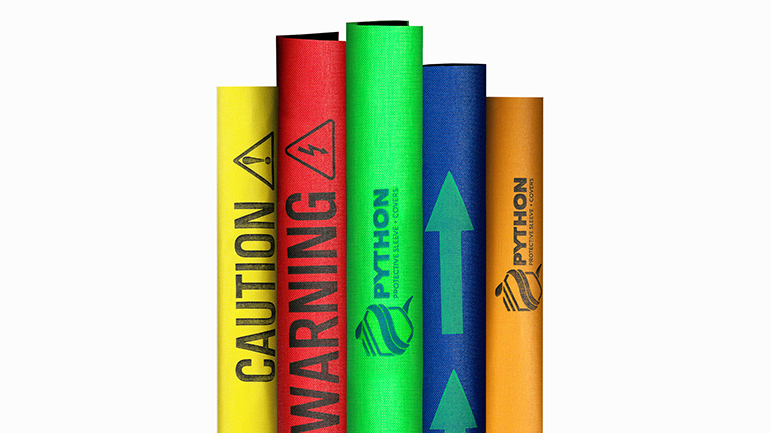

Either spiral or sleeve wraps come in various colors as an added feature that helps identify the sometimes numerous hoses that run through a particular pathway. For example, a hose wrap color may identify individual hoses or simply use red and blue to signify pressure and tank lines, respectively.

Filed Under: Engineering Basics, Hose & Tubing, Hose Assembly Tips