By Josh Cosford

Compared to many of you reading this, I am young in this industry, and as such, my fluid power career is sophomoric at best. Depending on your perspective, I am lucky (cursed) enough to experience the slow movement of time. Time does not fly for me, so the year 2006 seems a lifetime ago. It was before marriage, before children, before divorce. I was a 31-year-old man-about-town without the worldly experience, who managed a carwash.

Compared to many of you reading this, I am young in this industry, and as such, my fluid power career is sophomoric at best. Depending on your perspective, I am lucky (cursed) enough to experience the slow movement of time. Time does not fly for me, so the year 2006 seems a lifetime ago. It was before marriage, before children, before divorce. I was a 31-year-old man-about-town without the worldly experience, who managed a carwash.

The turning of thirty galvanized my notion I was no longer “young,” although I felt nothing like “old.” My body was young enough work a physical trade for twelve-hour shifts, and I could still easily recover from a night on the bottle slotted between two of those shifts. I had a lot of fun in my carwash days, which originated in the preceding millennium, and it provided me my foundation if fluid power.

I’m sure you’ve all paid attention to the machinery in a tunnel wash: the spray nozzles, the motorized cloths and brushes, the robotic arms, the automatic curtains etc. Nearly every component in that tunnel was operated by or with high-pressure air, water or oil. It was my job to fix every component in that tunnel, including the eight self-wash bays, leaving only the serious electrical work to contractors.

You’d think I’d have learned more about fluid power, having tinkered with components nearly every day. I’m proud of my penchant for learning, but I never had the paradigm shift telling me it (fluid power) meant anything in the grand scheme of things. I knew how to keep everything running well, and I even once programmed the relay-based PLC line-by-line, using a previous printout for reference. However, I’m disappointed I didn’t educate myself more deeply on what I was handling.

The chain-driven track used to pull vehicles through the wash was powered by a single hydraulic motor, which could easily tug a dozen cars without breaking a sweat. The speed was controlled by a venerable Brand 3-port flow control – you know … the kind with the little handle and graduated panel. Typical track speed was about 80 ft./min, but the flow control was accurate enough jump to 100 ft/min with a microscopic clockwise tap (clearly flow was too high from the pump). Because the Brand flow control is pressure compensated, it did a great job of maintaining 80 ft/min regardless if one or ten cars were being pulled.

I can recall another ignorant moment of mine as I had to replace “the tiny box with the plastic hoses going into it,” which itself had an electrical connection. This little box controlled the operation of the plastic curtains which automatically opened and closed at the entrance of the tunnel, preventing the high-pressure water from shooting out like a monstrous Super Soaker. I brought that little box to a local supplier, plopped it on the counter, and with my multitudinous technical vocabulary, I enquired, “can you get me this?”

I can still picture that little 5/2 solenoid valve in my head. It had a form B DIN connector, 1/4-in. NPT ports with brass compression fittings (push-to-connect was not yet popular in 2001), and a cream colored body. It was originally attached to the wall with a steel bracket but, because it had long since rusted away, I reattached it with cable ties. Hey, at least I didn’t use duct tape.

Anyway, not only am I lucky time moves glacially for me, but I’m also just as lucky good memories inherently stick, while I mentally side-step the bad. I always experience life transitions coming away with myriad warm memories. However, plainly as these words you read, the carwash days didn’t last.

The carwash era ended by what I considered to be poor business practice from the then-owner who purchased the business in 2003. He removed value-added services such as the interior wash, skimped instead of buying quality mechanical components and reduced staffing, which led to longer wait times for customers. He ended up laying off the other manager opposite my continental shift, and he worked in his stead to save money.

In the late summer of 2006, he gave me my walking papers as well, because I was his single largest expense next to taxes. His poor management left me bitter as I collected my things on that Friday, but I’m not the type of guy who sits around and feels sorry for myself, so I grabbed the local paper on the way home to filter through the classified section, looking for a new situation.

That same Friday, I sent my résumé to a dozen potential employers. The first response I received was from an industrial retailer, Princess Auto. Sure, laugh at the name, but it comes from their original store location on Princess Street in Winnipeg, Manitoba. Originally Princess Street Auto Wreckers, they expanded their product selection after WWII to sell army surplus. It turns out there was a lot of surplus hydraulic components on war machines, so they offered those as well.

As the Princess Auto business model evolved, they turned into a retail chain with locations across Canada. Unique to retailing was their offer of fluid power components. Their target market was mobile machinery, and they eventually started manufacturing hydraulic cylinders in Winnipeg as well. Because the general population has little knowledge of hydraulics, there was some liability involved in selling the products unless you knew what you’re doing. I’m certain you, like I, have been asked to install hydraulics on friends’ cars. I’m also certain your friends, like mine, have no idea how expensive hydraulics are – nor how much of a pain in the ass installing them in their car would be.

To combat fluid power ignorance, Princess Auto developed a training program. They brought team members from store locations bounding the oceans to their home office in Winnipeg, where they were educated to various degrees during intensive two-week sessions. They offered three levels of training; Hydraulic Specialist I, Hydraulic Specialist II, and Mobile Hydraulics Technician through the International Fluid Power Society. Some of the in-store hydraulic specialists took it further and enrolled in fluid power programs at local colleges, or achieved further IFPS certifications on their own time.

I had no interest in hydraulics when I applied at Princess Auto, however. In fact, I wasn’t even really aware of the position, initially. I applied to their position of Assistant Team Leader; I already managed a carwash mere days earlier. I continue through their two-week examination, at which point I was asked to take the open hydraulic specialist position, rather than the Assistant Team Leader role. I was chagrinned, and wasn’t so sure hydraulics was a direction I wanted to take, but I was given an assurance that there was plenty room to advance within the company. I took the role.

Literally two weeks after hire, a training session at the home office was offered, and I spent two more weeks learning their basic hydraulic course. I hadn’t yet fallen in love with hydraulics, but I fell in love with the company culture. They do all the right things a modern corporation does to encourage personal and professional development, and I knew I wanted to be part of the family.

After two weeks, I was back at the store in Hamilton, Ontario, and Princess Auto scheduled their second-tier training for six months later. If I recall correctly, I believe I was the first retail team member to be offered the Hydraulic Specialist II training within six months of employment. They typically wait for the team member to gain both in-store retail and general fluid power experience before furthering training. I guess I just got fluid power.

The first six months at Princess Auto went just as slowly as time normally travels for me, but I finally found myself back on a plane to Winnipeg for their Hydraulic Specialist II course. I learned about pressure compensation, through-centre valve circuits and two-stage pumps for logsplitters. As the fortnight came nigh, we also learned about load-sensing hydraulic circuits – this is when I fell in love with hydraulics.

So smitten with fluid power as I was, upon my return to Hamilton, I enrolled at Mohawk College for their Fluid Power Certificate Program. It consisted of eight, part-time evening classes, which I doubled up each semester. The schooling gave me the base knowledge to contribute highly to my role in fluid power retail, and looking back, I definitely thought I knew more than I realize now. Regardless, I knew I only had a taste, and my hunger for learning left my stomach in knots.

Mohawk also offered a review course for the IFPS’s Hydraulic Specialist certification, which on the last day of class was the independently proctored 3-hour exam. In September of 2008, I enrolled in this course. The year 2008 offered me plenty in the way of life-changing moments. I got married, bought a house and had my first child, but not in that order, if you catch my drift. But hey, since my life was upside down already, why not change employers as well?

I’m so thoroughly thankful to Princess Auto for kick-starting my career, but the fluid power oxygen being pumped into my forge left me yearning for more than they had to offer, so when the opportunity to grow was presented to me, I reluctantly moved on.

The Fluid Power House is your stereotypical fluid power distribution, engineering, and service company, who can troubleshoot your ailing machine or design an integrated circuit for your skid-steer attachment. I was lucky to have a close friend working there, and after a couple interviews, I was offered a position in outside sales. My supervisors did have one stipulation upon my hire, and it was that I completed – successfully – the HS certification to which I was enrolled.

Here’s the part when I do some horn tooting. I’m one of those fellows who is a quick study, and with the help of a fantastic instructor, I excelled in the HS review course. As the date came to write the exam, I was still nervous because of the number of students in my class who had failed the exam on previous occasions. We were given three hours to write the exam. In a short 45 minutes, I had completed my exam – twice, to be sure. When the results were posted online weeks later, I found my 94% score. I was disappointed I got two question incorrect.

Anyway, with the HS certification under my belt, I thought I knew everything I needed to know about fluid power. But in my early days at the Fluid Power House, one thing became clear early on; I didn’t know shit about fluid power. The owners of the company are pretty much fluid power geniuses. My learning curve was steep, but I can’t think of better mentors than the ones I had. I screwed up early and often … always in a rush, and always believing I knew something I didn’t.

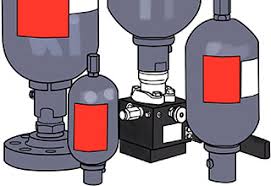

I was with The Fluid Power House for over six years, but I still remember my first day. There were thirty piston accumulators getting ready for shipment to a big customer, and I was given the task of charging them all. As mundane as this task would eventually seem, I was excited to get my hands on the valving and hoses required to transfer high-pressure nitrogen from storage tanks to accumulators. My only experience previous to this was when we rebuilt bladder accumulators back at Mohawk College. However, no nitrogen ever had the opportunity to cool my hands at school.

As much as I owe the start of my career to Princess Auto, I owe the explosion of my career to The Fluid Power House. My passion for education never cooled during my tenure there, and I was always learning, always growing. I wasn’t good at everything, but I could hold my own when designing hydraulic manifolds or troubleshooting large systems. I learned enough that I was eventually able to write about fluid power, something I’ve been doing on various levels since 2012.

Six years is a long time when traveling on a beam of light as I do (that one is for my fellow physics nerds). However, I eventually concluded outside sales was not my bag, baby (that one is for my fellow Austin Powers nerds). I left The Fluid Power House for inside sales at Higginson Equipment. I have soared here, and in a short period of time made a mark, resulting in promotions leading to the senior position I have now. Just as always, my fire to learn and grow is hot, and I find myself dealing with production, operations and sales, usually all on the same day.

In my relatively short fluid power career, I’ve come a long way. I am on the board of directors for the Canadian Fluid Power Association, I’ve spoken on behalf of Canada at the World Fluid Power Summit, I’m in upper management at a cylinder manufacturing company, and I write about fluid power for the amazing team at WTWH Media. Along the way, I’ve learned something interesting that differentiates those on either side of the fluid power fence – a detail that immediately qualifies someone as being in the “fluid power know” … or not.

Those who possess some, but not extraordinary, knowledge of fluid power, are scared by accumulators. There are cautions to be taken by them, of course, but not to the extent they should be avoided like rabid wolverines. It seems everyone has a story about an accumulator that went through a roof like an ICBM test launch. The fact is, accumulators are both safe and advantageous. Their uses are many, from energy storage to pulsation damping, and their safety concerns are no more relevant than the concerns of my friends whom believe my car is going to roll when I take an on-ramp like Vettel.

If you’re reading this and considering, or starting, a career in fluid power, let me tell you this; it doesn’t matter where you start, or what path you take. It only matters that you’re on the journey and you put your heart and soul into everything you do. I came from humble beginnings in fluid power, not even realizing I’d be where I am today. I’m not different from anyone else, and not given any advantage in life, so ask yourself this: are accumulators scary?

Filed Under: Mobile Hydraulic Tips, Slider