I recently chatted with Michael Haen, VP of Global Product Line Management, Fluid Power, for Gates Corp. about what’s new at the manufacturer of hydraulic hose assemblies and what they see is coming on the horizon in terms of technical updates.

Mary Gannon: You just did a big expansion of your PRO series. Tell us a little about this latest product development.

Mike Haen, VP of Global Product Line Management, Fluid Power, Gates Corp.

Mike Haen: We did just expand our PRO Series product line on both the hose and the couplings side of things. What we’re doing with our PRO series line is really just broadening the overall portfolio that we’re offering to the market. What you find with hydraulics — a lot of the challenges are just finding the right hose or the right hose assembly for that application and the demands of that application. By introducing and expanding our PRO Series product line were able to just reach more of those applications with both new customers and also our existing customer base.

Mary Gannon: So this was done to make users’ lives easier. What other interesting trends do you see happening with hydraulic hose assemblies?

Mike Haen: I think traditionally when we’ve talked about performance specific to hose assemblies, a lot of times the conversation is focused on pressure or impulse testing, particularly comparing to industry specifications and some multiple of two or three times the industry specifications. I think that definition of performance is changing and actually increasing and that’s based on the challenges that our customers are seeing. So there are a lot of new application-driven criteria that we’re seeing. One of the areas that we’ve been focusing some of our new products on is just “assemble-ability” or even the weight of the hydraulic hose assembly.

Another trend along those lines is that today’s equipment just has an increase in overall features and there are also some of the higher performance requirements that you alluded to, so all of that is putting more and more stuff onto the equipment. That’s making the available space to route things like hydraulic hose assemblies a lot more difficult. It makes the routing a lot more complex and all those routing challenges, environmental challenges, has really increased the application requirements for the hydraulic hose assembly.

We work obviously with our customers very closely and listen to them and watch them so that we’re making sure we’re coming up with product solutions that are going to solve what we see in today’s modern applications.

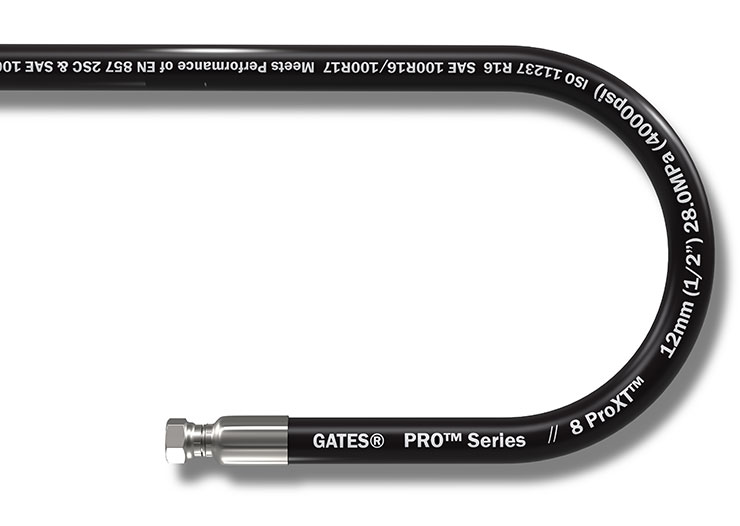

Gates Corp recently launched its ProXT line of hydraulic hose assemblies. Here is an example of its bend radius.

Mary Gannon: What about IoT, can you tell us a bit more about Gates’ products for smart tech and predictive maintenance?

Mike Haen: Yeah, that’s our Sentry line. I guess what I would say with that is that historically a lot of the equipment was over-engineered because we didn’t necessarily have that visibility into preventative maintenance and the reliability of the hose assemblies. But when you’re looking at the reliability or the predictability of the hose assembly itself, it’s not just the quality of the components but also the quality of that crimp and the hose coupling interface. That crimp is accomplished through a crimper and we’re certainly a leader in connected crimpers and all the opportunities that that provides. We’re very excited about the opportunities that IoT is going to bring to Gates.

Mary Gannon: Do you want to talk a little bit more about the crimpers? You have your own products in that regard, correct? And you also have special training for that.

Mike Haen: Yes. We do have an extensive crimper line that meets the needs of everything from the casual user to a higher volume user so we’re continuing to focus a lot of efforts into improving that line because, like I said, you’ve got the hose, you’ve got the coupling, but really where the performance really starts to be defined is with that crimped coupling and the hose coupling interface. We continue to innovate and evolve around all three aspects of our product line, being the hose, the coupling and the crimper.

Gates’ 32Tsi hose crimper

Mary Gannon: Any other thoughts you’d like to share about the future or does Gates see any different materials coming to play with hydraulic hose?

Mike Haen: Specific to Gates, we’re going to continue to differentiate through material science and process expertise. You talked about a lot of the new materials and the opportunities that provides into our product and so we plan to use that material science and process expertise to really reset the customer expectations with innovative products like MXT, which is a new product that we just introduced and demonstrates how all of those capabilities can kind of come to life into a hydraulic hose assembly. You can learn more about that on our website, which is gates.com, or our YouTube channel. MXT addresses a lot of the challenges that we talked about earlier, whether it’s weight, flexibility, multiple industry specifications into one hose so that you can really simplify your product selection, simplify our inventory and make sure that you’ve always got the right product on hand.

We also talked about some of the things that we’re doing with our PRO Series line and how that requires material and process expertise to make sure that you’re getting the right product developed for the right applications. Most of our discussion so far has been about hydraulics, but we also see a lot of opportunity with our entire fluid power portfolio, everything from modular engine hose assemblies to SCR hoses, our industrial hose line. Really within the entire Gates family of fluid power products we’ve got a lot of innovation in our pipeline that we’re really, really excited about.

Mary Gannon: Can’t wait to learn more as these new innovations are developed. Do you think the hydraulics side will continue to innovate with higher pressures and, if so, how will you change the products to suit those higher pressures?

Mike Haen: Yeah. Applications are requiring higher pressures and that’s aligned with the increased demand for productivity and performance out of the equipment where our products are applied. You mentioned hose in that question but the challenge really extends to both the couplings and that hose coupling interface. At Gates we already have a portfolio that exceeds a lot of the industry standards so we’re well positioned in that regard.

As far as how manufacturers will respond, it really just puts a premium more on getting more out of your materials and the designs themselves to be able to meet the needs of the customer engineers, particularly when faced with some of the other challenges I talked about too, weight and abrasion and the force to bend. You can really only get there, in my opinion, through innovation in materials and those manufacturing processes. It’s not just about meeting those pressure requirements but all the customer requirements. Like I said earlier too, we are constantly checking in with our customers to understand the roadmap of their product line so that we can make sure that we’re very well positioned with our products to support their application needs.

For more details on Gates’ hydraulics products, visit gates.com.

Filed Under: Fittings, Couplings & Adapters, Hose & Tubing, Hose Assembly Tips