Clippard has recently launched what it is calling its most revolutionary product in years — its Cordis proportional pressure controls. Meaning “of the heart” in Latin, Cordis is at the heart of all that is important at Clippard, said Rob Clippard, VP of Marketing.

Clippard’s Cordis proportional pressure controls use the proven EVP and DVP lines of electronic proportional valves, allowing for steady, repeatable downstream pressure as demand or processes change.

“Everyone wants a smarter product these days and so taking our technology and wrapping around that intelligence feedback from pressure sensors — from flow sensors, and from other types of devices, an electronic pressure controller is certainly the next phase, the next revolution of our product line,” Clippard said. “By having control over the manufacture of the valve, we have a great deal of discretion in the design of the entire pressure control unit and that adds value to our customers. It not only gives us the ability to select specific to applications, but it improves the overall turnaround time for getting product into the hands of our customers.”

Clippard’s new Cordis controls use the proven EVP and DVP lines of electronic proportional valves, allowing for steady, repeatable downstream pressure as demand or processes change. The result is a precise linear pressure control within a closed-loop system with ultra-high resolution and repeatability.

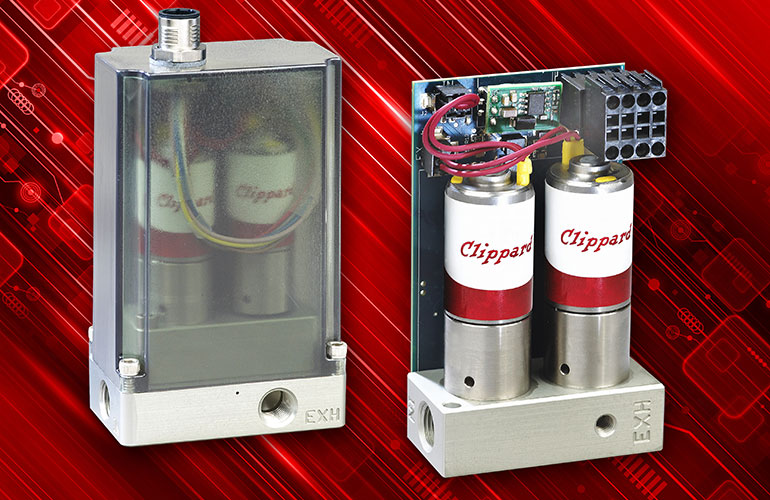

The Cordis uses a microcontroller, integrated pressure sensor, and two Clippard proportional valves. The inlet valve is connected to the moderately regulated supply pressure and the exhaust valve is connected to a port that vents excess pressure to atmosphere. Once a command is increased, the inlet valve opens up to allow supply pressure to pass over the sensor element that provides an active feedback for this microcontroller to satisfy the set point in the process. If at any point the sensor detects a value higher than the set point, the exhaust valve will open to vent off the excess pressure to maintain a stable and accurate control pressure in the process.

The normally-closed valves offer flows from 2.7 to 65 lpm and a typical response time of < 20 msec. Accuracy is ±0.05% of full scale and resolution is ≤ 5 mV. They are rated for temperatures from 32° to 120° F.

Cordis is available in both an unhoused unit for OEM instruments and a housed version which operates as a standalone unit.

The Cordis is adaptable to a variety of sensors that can close the loop around not only pressure, but vacuum or flow. It provides smooth linear control and offers integrated internal or external sensor feedback. In addition, it offers multiple flow configurations and can be used in static or dynamic applications with the same proportional regulation.

This electronic pressure control device takes a command signal and compares it to the output pressure of the unit, said Matt Larson, Product Manager.

“Our unit uses two proportional valves, one on the inlet, and one on the exhaust side to relieve any process pressure downstream. The software is proprietary to Clippard and is integrated into the controller to constantly compare the command signal to the output pressure of the units on the feedback side,” Larson said.

Clippard’s standard product range is 0 to 150 psi, and the valves can be rated for vacuum through positive pressure. As a result, these valves are highly customizable.

Different models are meant for different applications, said Ernie Doering, COO. “An unhoused unit is intended to go into an OEM instrument. We also have a housed version of Cordis, which is intended to be a standalone unit,” Doering said.

Typical applications would be in the leak test industry where they might be testing low flow, and low-pressure applications in the life science industry for needs such as DNA sequencing or DNA testing for diabetes. These applications require low volume, low flow, and low pressure and require very stable and high-resolution control.

“Through our software design that we’ve done in house, we’re able to make the unit very flexible for customer applications. These units are going to be used in those hard-to-do applications where low volume and high resolution is required,” Larson said. “What we’ve done in the past is with a straight analog unit; this unit would have to come back to the manufacturer and be preset based on the customer requirements. With the Cordis, the customer is actually allowed and able to log into the unit and adjust the settings directly at the machines based specifically on what they need the unit to do. We’re putting that decision in the customer’s hands.”

Clippard added, “Having a digitally based platform gives us unlimited flexibility in meeting the needs of our customers. It really puts us in a unique position to where we can develop this product around the customer’s needs. With the digital platform, we can do that quickly.”

Clippard

www.clippard.com

Filed Under: Pneumatic Tips